Editor’s choice

F-35 Bulkhead Overhaul Lets Fighter Hide Heavier Arms

Lockheed Martin reshaped a small yet vital slice of the F-35 frame. The fresh FS425…

Northrop Grumman Adding Mobile Targets to B-2 Bomber Capabilities

The B-2 Spirit edges into a new era. Air Force engineers push the bomber toward…

The F-35 Fighter Jet, The World’s Costliest Weapons Program, Just Got More Expensive

The Pentagon just raised the F-35 bill again. Numbers inside its fresh acquisition report point…

Latest articles

Direct Toronto–Istanbul Flights Start in December 2025 with New Air Transat-Turkish Airlines Tie-Up

Air Transat will open a direct link between Toronto Pearson and Istanbul on 6 December…

Spain pushes back on 5 % defense quota, advocates integrated EU-NATO investment framework

Prime Minister Pedro Sánchez has notified NATO headquarters that Spain will not accept a future…

Lockheed Martin Turns to Europe to Fix Missile Bottlenecks and Meet Soaring Alliance Demand

Lockheed Martin has entered a surge phase. More missiles leave its U.S. plants than ever,…

Airbus Advances MRTT+ Tanker Production While France Green-Lights VSR700 Naval Drone

Airbus used the mid-week peak of Le Bourget to firm up two programs that matter…

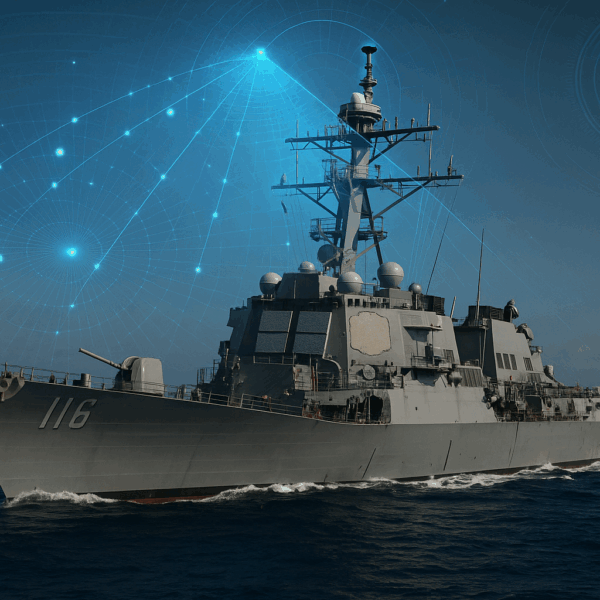

Hybrid Base Station Sniper Pod Upgrade Enables F-35 to Share Sensor Data with 4th-Gen Aircraft

The Defense-Aerospace editorial team has confirmed that Lockheed Martin is pressing ahead with the Hybrid…

Sweden Shifts 3.5 % GDP Defense Spending Target to 2032 Ahead of NATO Summit

Sweden will now aim to spend 3.5 percent of its gross domestic product on defense…

Poland Receives First AH-64D Apaches to Prepare for Guardian Fleet

Three AH-64D Apache attack helicopters landed this morning at the 56th Air Base in Latkowo,…

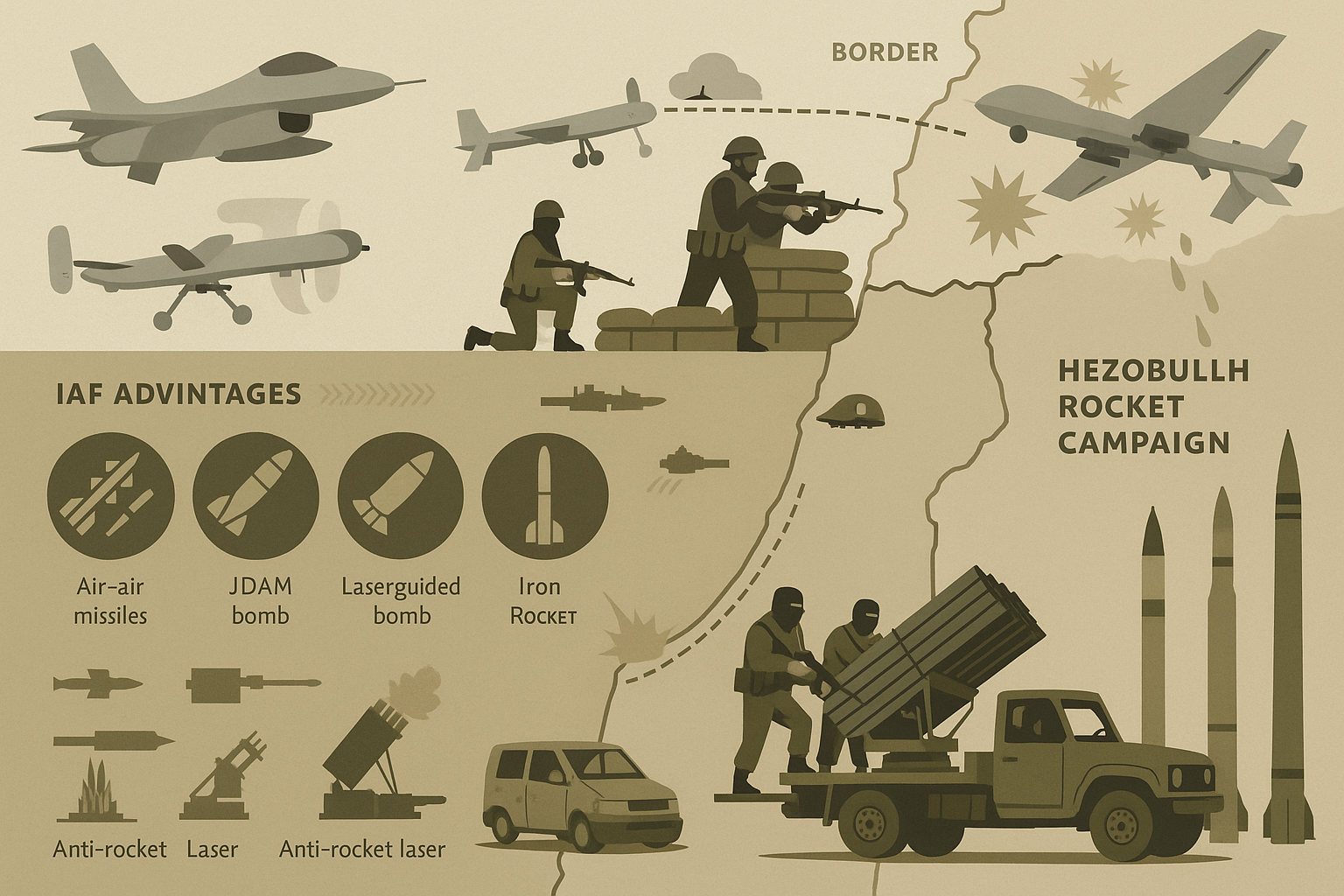

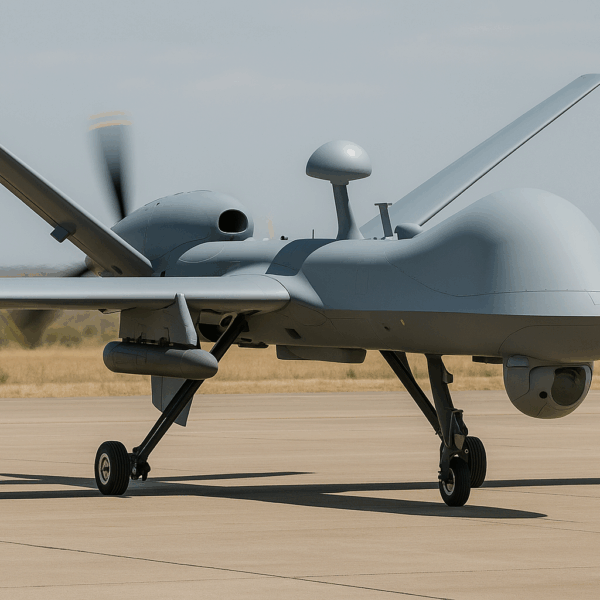

China’s Expanding Drone Arsenal Reveals Strength of Civil-Military Integration

The first taxi runs of Jiutian’s SS-UAV “drone mothership” at a private airfield in Sichuan…