Feature Stories

Milestone for AIR 5391

The Systems Division of Tenix Defence Systems today closed the Critical Design Review for the ELTA EL/L-8222 electronic-countermeasures pod Software Support Facility. Built…

Raytheon Wins $321 Million Order for More Silent Knight Radars

The contract keeps Raytheon busy well into 2028. The firm will push out more Silent Knight units, spares, an updated software pack, plus…

Training for the Mission – Ukrainians Learn to Operate the Leopard 1 A5

Every tank feels different. Controls on a T-72 ask for muscle memory, while the Leopard’s clutch and gearbox demand a softer touch. “The…

GAO Reports Highlight New F-35 Deficiencies

The Government Accountability Office released two companion studies dated April 25 that paint a stark picture of the F-35’s technical health and budget…

Press releases

Taranis UCAV Marks A Decade of Quiet Influence in British Air Power

The Taranis unmanned combat air vehicle once showed up in the corner of BAE Systems’ Warton site, almost out of sight. At first…

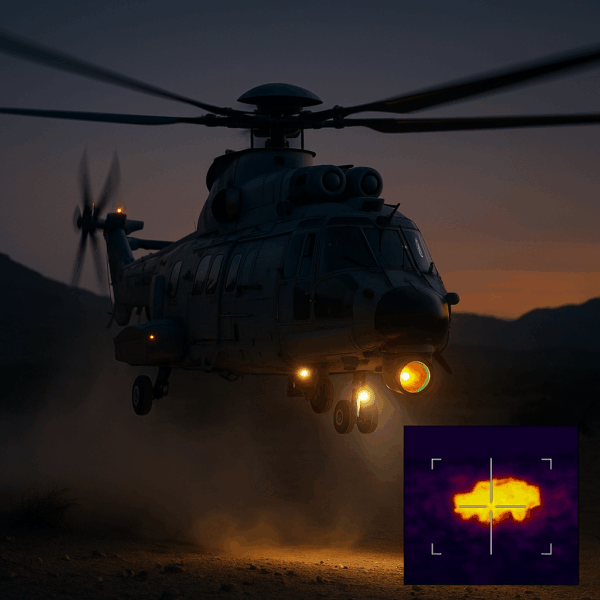

Sagem’s Euroflir 350 Optronic Observation System Chosen for Caracal Helicopters Deployed by French Special Forces

Eurocopter has picked Sagem’s new Euroflir 350 sight for the EC725 Caracal fleet that supports French special operations. The move links a fresh…

Romanias M1A2 Abrams Tank Buy to Cost 1.07 billion — Defense Ministry

Romania locked in a $1.07 billion plan to buy M1A2 SEPv3 Abrams tanks. Officials call it a clean break from its aging Soviet…

Agreement on Maintenance of Long-Range and Medium-Range Surveillance Radars Extended

Finland has decided to keep its backbone air-surveillance radars in shape for another five years. Defence Minister Jussi Niinistö authorized the Defence Forces…

Editor’s choice

General Dynamics Electric Boat Secures $1.85 B Navy Contract for Virginia-Class Block VI Submarine Prep

According to industry sources, the U.S. Navy has added up to $1.85 billion to its multiyear Virginia-class attack-submarine contract with General Dynamics Electric Boat. The money covers early construction work and the purchase of long-lead components for the forthcoming Block VI boats. Defense officials confirm…

Thales Signs £700 Million Watchkeeper Contract with MoD

The Ministry of Defence has signed a £700 million agreement with Thales UK to develop, manufacture, and support the Watchkeeper unmanned system. The single signature secures every major phase of work, from completing design through initial sustainment, under one integrated schedule.

China’s Expanding Drone Arsenal Reveals Strength of Civil-Military Integration

The first taxi runs of Jiutian’s SS-UAV “drone mothership” at a private airfield in Sichuan on 16 June reflect how far China’s unmanned programs have moved in a single decade. According to industry sources, technicians completed telemetry checks in less than six weeks, after the…

Latest articles

Arquus and Daimler Truck Launch Joint Bid to Modernize French Military Truck Fleet

THE HAGUE, Netherlands – French armored-vehicle specialist Arquus and German commercial-vehicle giant Daimler Truck have…

How the $150 Billion Defense Reconciliation Bill Rebuilds U.S. Military Capability

The Senate’s narrow vote on July 1 sent a 940-page reconciliation measure – nicknamed the…

$25 Million Set Aside as Army Plans 2026 Tests of Blackbeard Hypersonic Round on Autonomous Launchers

The Army is moving fast to fold a new hypersonic strike option into its tactical…

US Navy’s Large Scale Exercise 2025 Welcomes Canadian, Japanese and NATO Liaison Teams

The U.S. Navy will run its third Large Scale Exercise (LSE 25) from late July…

Pentagon’s $1.01 Trillion 2026 Plan Funds 19 Navy Vessels to Counter China and Middle East Risks

The Pentagon has filed its fiscal 2026 request with Congress. Defense officials confirm the document…

Royal Australian Navy Welcomes HMAS Arafura as New Arafura-Class OPV

The Royal Australian Navy has added a new hull to its order of battle. On…

U.S. Army Debuts Stryker-Mounted DE M-SHORAD Laser in Live Field Test

Soldiers at Fort Sill fired a Stryker-mounted laser in a real tactical drill for the…

U.S. Army Commences 2025 Production of IFPC Increment 2 to Strengthen Mid-Tier Air Defense

The Army has given the green light to start low-rate production of its Indirect Fire…