US Air Force to Expand KC‑46 Fleet with Up to 75 Additional Jets

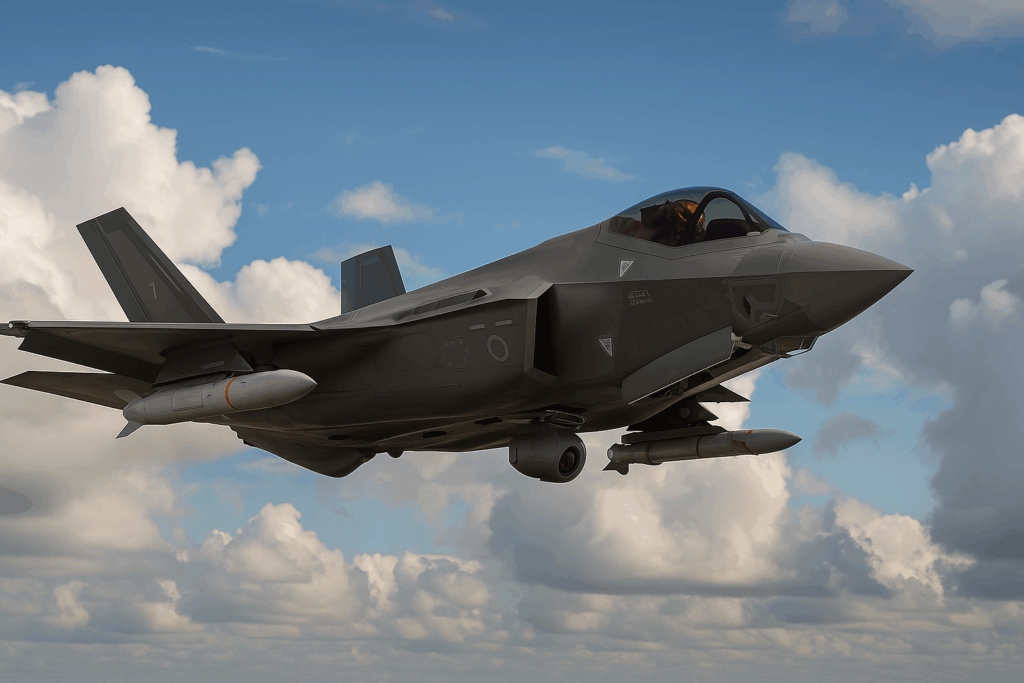

U.S. Air Force photo by Staff Sgt. Mary McKnight

The U.S. Air Force has authorized an extension to KC-46A production for up to 75 additional aircraft. Senior leaders announced this decision in the past two weeks to sustain the tanker recapitalization line once the current contract expires. Under the original 2011 agreement, the program of record has already expanded to 188 aircraft, reaching that contracts contractual ceiling. The new block of 75 planes sits atop the existing deal and carries the service into the next phase of its tanker roadmap.

That roadmap no longer includes a competitive process for an interim “bridge” tanker. After years of study, the Air Force has opted to procure more KC-46s. Considerations of budget, capacity and risk drove the choice, as did the simple fact that KC-135s must be retired without creating an operational gap. Industry sources note that the extension provides predictable deliveries and spare parts while the long-term tanker concept matures.

Public Endorsement at RIAT

Gen. David Allvin, Chief of Staff of the Air Force, confirmed the acquisition strategy publicly at the Royal International Air Tattoo in late July. He stated that the plan is approved for up to 75 additional KC-46As as part of the ongoing KC-135 recapitalization effort. That announcement dispelled any remaining uncertainty about restarting a tanker competition.

The Air Force has increased the contract ceiling from 179 to 188 KC-46As-the maximum under the original deal-and the new extension sits on top of that block. If every option is exercised, the total fleet could exceed 260 aircraft, aligning tanker availability with daily mission requirements even as older jets enter depot maintenance or retire

Legacy KC-135 Fleet vs. KC-46 Advantages.

More than 370 KC-135s remain active across the Air Force in various configurations. Their average age sits in the mid-60s. Some joined the service seven decades ago. Sustainment teams keep them reliable but time adds cost, inspections and downtime. By contrast, the KC-46 offers common avionics across lots, modern wiring and plumbing, and a 767-based airframe that the depot system knows well.

The extension program forms the backbone of near-term planning. It tackles a single issue: increasing capacity without revisiting requirements or launching a new competition. Defense officials say the Air Force will adjust contract terms when Boeing delivers the aircraft already covered by the capped program of record. The Everett production line will continue without interruption. The Air Force’s goal is steady progress, not a stop-start cycle that could disrupt the workforce or create a parts backlog.

Current Operational Status

There are 93 KC-46s in service right now, according to Cirium’s fleet data from last week. Deliveries picked up again in late spring after a brief hold to fix structural cracks on newer airframes, and the total keeps growing as jets finish production and acceptance checks. The service life extension plan is designed to keep that momentum going, with units converting at McConnell, Pease, Travis, McGuire-Dix-Lakehurst, Seymour Johnson and several other bases.

FY 26 Budget and Upgrade Funding

FY 26 budgets set aside about $2.8 billion for 15 more KC-46s-roughly $186 million apiece. The Air Force has also reserved tens of millions for upgrades, either added during production or sent later as retrofit kits. Those updates cover tougher comms systems, software improvements and cockpit tweaks, all scheduled around depot visits to keep the downtime low.

The refueling gear is still under the microscope, with the Remote Vision System 2.0 upgrade leading the pack. Due before the decade’s end, it should sharpen the camera feed, cut operator workload and work better in all lighting. A number of other top-priority issues have already been fixed through retrofit kits or in newer production runs. After this year’s crack discovery, acceptance teams have doubled down on inspections of both delivered and fresh-off-the-line aircraft.

Extending KC-46 production also shows where the “bridge tanker” idea stands. In 2023, Lockheed Martin dropped out of the LMXT competition it’d teamed up on with Airbus. That left the Air Force with fewer options for a mid-term tanker contest and put more focus on keeping the Pegasus line going. Meanwhile, Congress has blocked taking KC-135s out of service until there’s a clear plan for what comes next. Pumping out more KC-46s fills that gap for now, even as the follow-on tanker project-known as – NGAS – moves into a lower-definition phase with fewer funds in the FY26 budget.

What really drives this, though, is how many missions the Air Force needs to support. Tankers set the pace for everything from bomber deployments and homeland defence to fighter deployments and big exercises. Commanders want planes that can fly long distances, link up with joint networks, haul cargo, carry medevac gear and keep going. Right now, the KC-46 does all that. Over the last two years, Air Mobility Command has sent these jets all over the globe and crews have racked up hours on long flights, night refueling runs and quick-turn missions.

Training in Lockstep with Deliveries

Conversions include new simulators, revised ground-support equipment and squadron-level maintenance courses. Extending the production line gives instructors and schedulers a reliable delivery schedule. According to industry sources, training units have already aligned class sizes with projected KC-46 arrivals through FY27, which should prevent bottlenecks for boom operators and maintenance personnel.

Keeping the production line running also preserves a skilled workforce in Washington state and steadies a supply chain spanning structures to avionics. A consistent build rate curbs the cost increases that come from stop-start production, and secures configuration control and technical-data access since both contractor and Air Force share a clear plan for multiple lots. That doesn’t eliminate every risk but it reduces the chance of unexptected problems.

Air Force leaders continue to explore survivability for the next-generation tanker. Concepts under study include distributed fuel nodes, advanced countermeasures and teaming architectures, rather than a single large airframe. Extending KC-46 production doesn’t foreclose those options-it maintains capacity today, buys time for research and analysis, and keeps squadrons mission-ready.

KC-46 Procurement Costs, Deliveries, and Fleet Impact

The program of record is capped at 188 KC-46 aircraft, with authority to build up to 75 more-bringing a potential total to 263 if the full extension is exercised. As of late July, 93 KC-46s are operational. The KC-135 fleet still numbers over 370 airframes and averages an age comparable to retiring personnel.

Cost trends mirror other mature airlifter and tanker lines. After initial learning-curve effects, unit flyaway costs stabilize, then vary with avionics insertions or inflation. The FY 26 price-about $186 million per jet, including government-furnished equipment and support-aligns with recent production lots. That figure reflects the complexity of a wide-body tanker equipped with military-grade wiring, hardened systems, and a refueling boom.

Defects and contract penalties continue to draw scrutiny. Since 2014, Boeing has logged multi-billion-dollar charges under the fixed-price KC-46 contract, and quality escapes this year prompted a pause in deliveries. At the same time, the KC-46’s operational record is expanding: combatant commands repeatedly request Pegasus tankers for active missions. Unit logs show sorties launched, fuel offloads meeting plans, cargo moved, and aeromedical patients transported under controlled care.

Foreign demand provides added support for the U.S. buy. Japan already flies the KC-46 and has placed follow-on orders. Israel has contracted for four jets and intends to order more. Other air forces have evaluated the platform, though tighter budgets and industrial tradeoffs tend to slow their decisions. While these export prospects don’t drive the U.S. choice, they strengthen supply-chain stability, spare-parts commonality and software baselines by enlarging the user community.

The key unanswered question remains NGAS. FY 26 funding for the next-generation family of systems has been reduced as the Air Force narrows its requirements. Some leaders emphasize a survivable tanker with low observability and advanced electronic warfare suites; others favor distributed refueling concepts that complicate enemy targeting. Until those design decisions are settled, the fleet still needs more tankers. Extending the KC-46 line meets that need without locking the service into a single future architecture.

As the extension ramps up, crews and maintainers will notice several near-term changes:

- Conversion pacing: Units in line for KC-46 conversion will see fewer gaps between acceptance, training, and operational test activity. That cuts the risk of sending personnel to other bases for long cross-flows.

- Depot and parts flow: Predictable lots enable depot planners to schedule heavy checks and retrofit windows with less conflict against operational taskings. Suppliers can more accurately anticipate the quantities of booms, valves, brackets and avionics required.

Lockheed Martin’s 2023 exit from the LMXT bid ended the bridge-tanker track. Airbus showed interest, but the Air Force opted to extend KC-46 production. That move, alongside a pared-down NGAS study, meets Congress’s requirement tying KC-135 retirements to a clear follow-on plan and removes the near-term vs. long-term dilemma.

KC-46A Production Extension – Dates, Quantities, and Budget Signals

Between July 20 and 25, senior leaders confirmed extending production by up to 75 KC-46s, lifting the 2011 contract’s program of record to 188. FY 26 budgets fund 15 jets at about $2.8 billion and include upgrade funding for communications and refueling systems. Deliveries resumed in late spring after a crack-related pause and have remained steady into August, while training units have matched class loads to projected deliveries over the next several fiscal years.

If the Air Force accepts all 188 KC-46s and exercises the full 75-aircraft extension, the fleet could reach roughly 263 tankers. That total smooths the KC-135 retirement curve, preserves surge capacity, and expands the pool of qualified operators and maintainers, easing rotation pressures and enhancing unit continuity.

The Air Force opted for continuity, buying the KC-46 at a steady pace with defined upgrades and a mature supply base. KC-135s will remain in service for years and their replacment no longer depends on a contested competition. NGAS continues with reduced FY26 funding and an open-ended design that will take time to finalise.

Defense-Aerospace will monitor the extension’s contract terms, the RVS 2.0 installation schedule, KC-135 retirement rates tied to KC-46 deliveries, base conversion sequencing, and depot workload distribution as the KC-46 fleet expands.

REFERENCE SOURCES

- https://www.defensenews.com/air/2025/07/14/images-show-shredded-kc-46-boom-that-led-to-emergency-landing/

- https://www.defenseone.com/policy/2025/07/air-force-will-buy-more-kc-46s-skip-competition/406850/

- https://breakingdefense.com/2025/07/air-force-again-changes-course-on-tankers-plans-new-production-extension-program/

- https://www.airandspaceforces.com/air-force-to-buy-more-kc-46/

- https://www.flightglobal.com/fixed-wing/us-air-force-to-purchase-dozens-more-kc-46-tankers-from-boeing/163946.article

- https://breakingdefense.com/2025/06/pentagon-procurement-budget-fy26-reconciliation-f35-bombs-f15ex-army-navy-air-force-space-force-trump/

- https://www.airandspaceforces.com/deliveries-kc-46-resume-cracking-issue/

- https://www.defensenews.com/air/2025/05/07/kc-46-vision-system-upgrade-slips-to-2027-three-years-behind-schedule/

- https://www.murray.senate.gov/senator-murray-statement-on-air-force-extending-kc-46a-tanker-contract-award-to-acquire-up-to-75-additional-aircraft-produced-in-everett-wa/

- https://www.boeing.com/defense/kc-46a-pegasus-tanker