Early F-135 advocates promised a smooth learning curve. They said each production lot would cost less than the one before. Fresh data show the opposite. Unit prices still hover near $30 million, even though annual output has more than doubled since 2011. The F-35 program’s $438 billion cost continues to draw scrutiny as production and sustainment expenses climb.

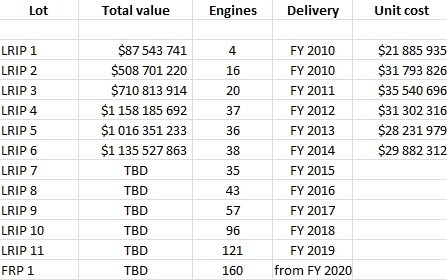

Pentagon auditors counted 16 engines in Low-Rate Initial Production (LRIP) Lot 2. The government paid an average of $31.8 million each. Four years later, LRIP 6 delivered 38 engines at $29.9 million apiece—only a six-percent drop. Worse, that Lot 6 price was higher than Lot 5 by roughly six percent, breaking the expected downward slope.

F135 Engine Cost Defies Expected Learning Curve Trends

The learning-curve theory rests on three ideas:

- Bigger annual orders should unlock bulk discounts on raw materials.

- A stable design should let suppliers refine tooling and trim scrap.

- Repetition should speed assembly and cut labor hours.

None of those benefits appear in the ledger. Year-to-year swings range from minus 8 percent to plus 12 percent with no link to the engine count.

Program managers blame four pressure points:

- Frequent design tweaks to address cracking and overheating.

- Parallel testing and production that forces costly re-work.

- Tight titanium markets that amplify commodity price shocks.

- Quality lapses flagged by government inspectors—61 violations logged in a single 2015 visit.

F-35 Unit Cost Challenges Tied to Engine Sustainment and Reliability

The GAO found the engine fails every 25 flight hours on average, far short of the 100-hour interim goal for the conventional variant.

Congress has noticed. The House Tactical Air and Land Forces Subcommittee ordered an independent review of the F-135’s cost and reliability history. Lawmakers want concrete options to reverse the trend before full-rate production. The report is due in March 2016.

Pratt & Whitney argues that newer builds already meet specification and that unit cost will fall once design is stable. Company officials cite the 2013 LRIP 6 agreement—$1.1 billion for 38 engines—as proof the price curve bends the right way. However, the F-35 engine remains compromised despite upgrades, raising doubts about whether new iterations solve persistent design issues.

Sustainment projections add fresh risk. The engine alone accounts for more than one-third of the Joint Program Office’s fly-away cost goal of $80-85 million per F-35A by 2019. If the power-plant price refuses to drop, the airframe target becomes unreachable.

F35 Program Cost Impacted by Long-Term Engine and Sustainment Bills

Export customers share the pain. Each partner nation buys engines separately from airframes, so every unexpected uptick hits foreign budgets without recourse to U.S. multiyear contracts. Several European defense officials privately warn that engine overruns may crowd out pilot-training funds.

Looking ahead, LRIP 7 and 8 will raise the annual engine count past 60. Program officers insist that volume will finally unlock savings. The next twelve months will test that claim. Meanwhile, field units brace for extra downtime as early engines cycle through retrofit lines to cure durability faults.

F135 Engine Upgrade Effort Faces Delays – March 2025 Update

A decade has passed, yet the cost picture remains cloudy. In March 2023 the Pentagon halted plans for a brand-new adaptive engine and chose instead to keep the F-135 family alive through an Engine Core Upgrade (ECU). The Air Force says the ECU is cheaper and compatible with all three fighter variants.

That choice did not arrest spending. On Sept. 30 2024 the Department of Defense awarded Pratt & Whitney an undefinitized $1.31 billion contract to mature the ECU design, with completion slated for March 2028. The company targets 2029 for first operational installation, four years later than early marketing slides.

Today’s list price for a baseline F-135 stands near $36 million, erasing any savings achieved between 2015 and 2018. Inflation explains part of the rise, but sustainment demands drive the larger spike — including the $38 billion cost of fixing the engine. GAO’s 2024 report pegs lifetime engine support at more than $1.58 trillion across the fleet, up 44 percent from the 2018 estimate.

Fleet experience underscores the challenge. The engine crossed one million flight hours in March 2025, yet mean time between failures hovers around 45 hours—half the Block 4 requirement. Lockheed Martin now studies new cooling solutions because the upgraded avionics demand more power and bleed air than the core can supply. Executives expect to pick a thermal management architecture within two years.

International partners feel the squeeze. Canada’s Parliamentary Budget Officer raised the projected national F-35 program bill to C$74 billion, citing engine upgrade uncertainty as a cost driver. Other operators weigh whether to retrofit early blocks or wait for post-2029 production.

Pratt & Whitney points to the ECU as a reset button. Company briefings claim the revised core will deliver 10 percent thrust growth, 50 percent thermal margin, and no unit-price penalty compared with current builds. Critics reply that similar promises in 2015 never reached the invoice.

For now, the cost graph still refuses to slope down. Pentagon managers admit the engine line will need “stable, predictable funding” through at least FY 2030. With production ramping toward 175 jets a year, any slip in ECU schedule could force another round of retrofit bills.

REFERENCE SOURCES

- https://www.gao.gov/blog/f-35-will-now-exceed-2-trillion-military-plans-fly-it-less

- https://media.defense.gov/2015/Apr/27/2001713495/-1/-1/1/DODIG-2015-111.pdf

- https://www.gao.gov/assets/gao-15-364.pdf

- https://www.washingtonpost.com/business/economy/engine-maker-defends-f-35-as-investigators-find-new-problems/2015/04/27/40ce66e4-ed04-11e4-8666-a1d756d0218e_story.html

- https://www.bloomberg.com/news/articles/2015-04-27/f-35-engines-from-united-technologies-called-unreliable-by-gao

- https://www.americanmachinist.com/news/article/21898688/us-inspectors-raise-caution-on-f-35-engine-program

- https://www.airandspaceforces.com/pratt-whitney-mature-f-35-engine-core-upgrade/

- https://breakingdefense.com/2024/10/pentagon-awards-pratt-1-3-billion-to-continue-work-on-f-35-engine-upgrade/

- https://breakingdefense.com/2024/02/pratt-whitney-targets-2029-for-upgraded-f-35-engine-deliveries/

- https://www.prattwhitney.com/en/newsroom/news/2024/03/23/rtxs-pratt-whitney-receives-full-funding-for-f135-engine-core-upgrade

- https://www.janes.com/osint-insights/defence-news-details/pentagon-budget-2024-usaf-selects-f135-engine-core-upgrade-to-power-f-35

- https://www.rtx.com/news/news-center/2025/03/03/rtxs-pratt-whitney-f135-engine-surpasses-1-million-flight-hours

- https://breakingdefense.com/2025/03/lockheed-eyes-two-year-timeline-to-pick-new-f-35-cooling-system/

- https://www.gao.gov/assets/gao-24-106909.pdf